Wesley Clover Solutions (WCS), (acquired by Beanfield metroconnect) telecommunications solutions company based in Ottawa, Canada, approached Geekland to design and manufacture their next-generation IP-based multi-channel desktop conferencing system, commonly known as a Trading Turret. This IP-based Trading Turret is intended for use by traders on Wall Street and other financial trading institutions, enabling them to communicate with multiple parties simultaneously and execute trades quickly and efficiently.

Business Requirements

Wall Street and other high-volume commodities and stock traders often need to communicate with multiple parties simultaneously, switching channels to negotiate and execute trades. They typically use a specialized multi-channel telephone system called a Trading Turret, which provides multiple pre-programmed hot keys to connect with different parties and manage multiple channels. Most existing systems on the market were TDM-based and limited in traditional features. To leverage the richer and more flexible capabilities of IP-based telephony were the goals of the project.

WCS aimed to introduce a new fully IP-based trading turret to their existing and new customers who were constrained by the limited features of their current devices. The IP-based Trading Turret would not only provide traders with a flexible, expandable, and feature-rich platform but also future-proof their operations, allowing new features to be introduced dynamically.

The system consists of a main Control Module that handles all core functionalities, with additional modules that can be added as needed for expansion. The main Control Module could be packaged and installed stand alone and offers full conferencing capability. With a 5” touchscreen running on Android OS, this Control Module provided traders with a user-friendly interface to look up and call users in the contact list. The hot keys allowed the traders to quickly engage with their regular clients.

Besides the built-in speaker system, the Command Module also supported a regular telephony handset and a goose neck microphone. The audio system that was implemented

The Solution

The development of the new IP-based trading turret was a collaborative effort between Geekland and WCS engineering teams, each contributing their specific expertise to design the platform from concept to production-ready prototype. The new Trading Turret was designed to be modular and extensible to support higher volumes. It consisted of a main Control Module that provided core functionality for audio/video conferencing. This control module featured a traditional keypad for dialing contacts and hot keys that allowed traders to quickly call their regular contacts.

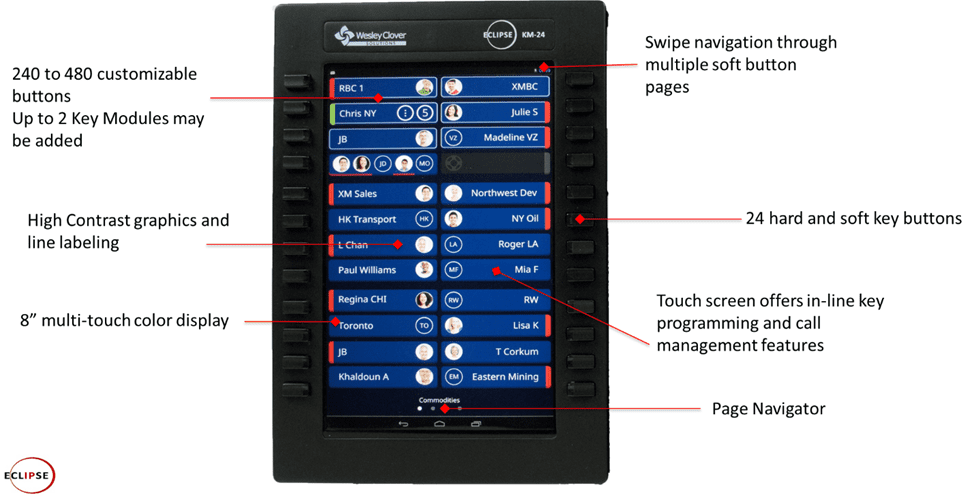

For power traders needing to contact more clients, the solution enabled the addition of an expansion Key Module that attached to the main Control Module and communicated via USB. Multiple Key Modules could be attached to the main Control Module as needed. These Key Modules featured 8-inch displays with associated hot keys supporting multiple pages all while deriving power and data from the Control Module.

The Main Control Module

The Main Control Module can be packaged and installed stand alone and offered full conferencing capability. With a 5” touchscreen running on Android OS, this Control Module provided traders with a user-friendly interface to look up and call users in the contact list. The 8 hot keys allowed the traders to quickly call their regular clients.

Besides the built-in speaker system, the Command Module also supported a regular telephony handset and a goose neck microphone. The audio system that was implemented allowed for up to 10 channels of simultaneous calls and consisted of front built-in speakers for handsfree conference calls.

The Trading Turret Main Command Module was built around an ARM/IMX6 quad-core Single Board Computer (SBC) running Android OS while a more compact IMX6 dual-core SBC was selected for each of the expansion modules. Power and data connectivity were provided via Power over Ethernet (PoE) for the main base, which also supported dual PoE ports for resiliency. Each expandable module connected and communicated with the main base via USB. Additionally, the main base unit supports WiFi and Bluetooth allowing it to connect to a user’s wireless network.

Using the IMX6 custom SOM from Variscite, Geekland designed the main base SBC to support all the subtending functionality. The IMX6 platform supported multiple GPIOs that were used to support several button keys on the Trading turret. The main base motherboard also required the POE support for power distribution both to the main turret module and to the subtending expansion modules.

For display, the main base unit featured a 5-inch industrial-grade touchscreen, while the expandable Key Modules were equipped with 8-inch touchscreen displays.

Development Phase

As this project was “from the ground up”, the development was broken down into several phases.

Joint industrial design. An industrial designer was engaged by WCS to design the product with functional and aesthetic considerations that would propel the product into a market with an innovative look and feature rich functionality. This was an interactive process between the industrial designer and the hardware engineering team to determine what was feasible from actual development and manufacturing.

Mechanical design

Once the industrial design was agreed to, Geekland’s engineering team then created the mechanical design on CAD for both the casing and the hardware boards. The mechanical design covered the entire product including the casing structure, the elastomers for the keys and the internal mountings for the hardware motherboards.

Rapid Prototype (Casing only)

Following the mechanical design, a rough model, via rapid prototyping, was created to validate the overall design and garner feedback from the WCS product team. The Rapid prototype model was developed using a fast CNC process similar to 3D printing but more representative of how the product will look like in the production following injection molding.

Hardware Board and Firmware development

In parallel with the mechanical design, the hardware engineering team designed the schematics for the motherboards used in the product. There were two main motherboards, one for the Command Module and the other for the expansion Key Module. Design reviews were conducted on the schematics and other aspects of the hardware design with particular emphasis to EMC and ESD considerations.

Following the design review, Geekland developed motherboard prototypes following PCB fabrication and SMT production.

The prototype motherboards were provided to WCS engineering to develop and test their application. Due to some issues identified at this stage, a second round of motherboard prototypes were built.

Overall, three rounds of prototypes that covered both the motherboards and the casing were built before the approvals for the Injection mold process for the casing.

Tooling for the casing

Following approvals of the prototypes created during the rapid prototype phase, Geekland then moved to the tooling phase for the cases, the light pipes, the keys and their elastomers. The keys and elastomers required a specialized shop that had experience with the use of LED lighting in this use case.

The injection molded plastics were provided to get feed back from WCS. Texturing and color was applied on the prototypes to get the look and feel approved by the product team. The team also tested with use of the elastomers with the keys to ensure consistency is the areas of key travel (from key rest to full depression), concavity (the depression on the key where the finger comes into contact) and tactile response (how much resistence the elastomer provides as resistence to a push). In addition, the team tested key presses to insure there weren’t issues of keys binding or sticking as well as system responsiveness to a key press.

Prototyping (Up to 5 samples are provided for testing)

A total of 5 samples were created for prototyping. These were full featured products used by the engineering teams for a variety of tests. These prototypes were also sent to certification labs for EMC and safety testing.

Regulatory approval (FCC, CE and for other countries)

Manufacturing Phase

This involves full production build, assembly, and testing. MOQ (500 units)

Part of the production phase included the implementation of a customer developed full device test plans. Working in conjunction with WCS the factory implemented a test harness that automated the functional testing and burn-in process ensuring 100% working units before shipment.

The Result

The Trading Turret was delivered to WCS after about two years, transitioning from the concept phase to manufacturing affording the client the opportunity to custom design the operating and application software that animates their new devices. Despite the lengthy duration, the project’s complexity and rigorous testing necessitated this extensive development and testing period. The outcome was a durable, rugged, and highly reliable system that met the 24/7 mission-critical operational requirements of the client’s customers. This fully IP-based solution revolutionized operations at trading firms by leveraging a modern platform to boost productivity.

Choosing the IMX6 CPU platform proved to be an excellent decision, offering extensibility and reliability. The failure rate was remarkably low, less than 1%, even after three years of operation. Additionally, the product life cycle and OS support were sustained for over five years.

This Geekland ODM case study underscores the potential of custom-built, innovative technological solutions in enhancing operational efficiency and user satisfaction. Geekland showcased its ability to design and manufacture highly complex products, such as the Turret, from concept to mass production. It also demonstrates Geeklands ability to working with international design teams operating across multiples countries and cultures.